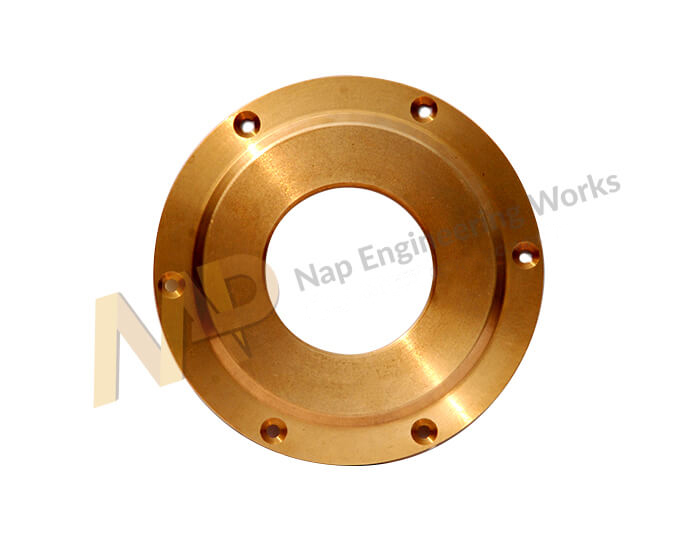

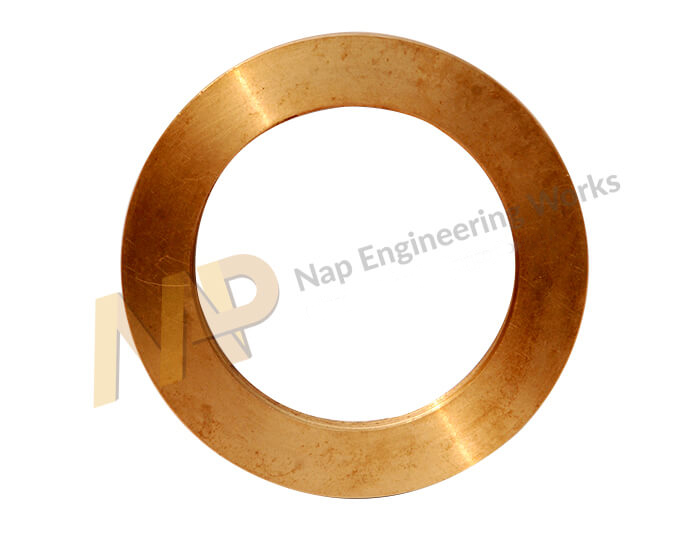

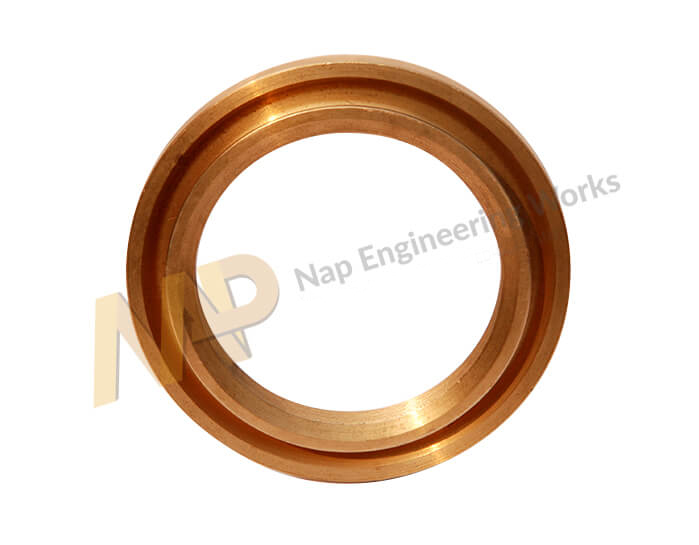

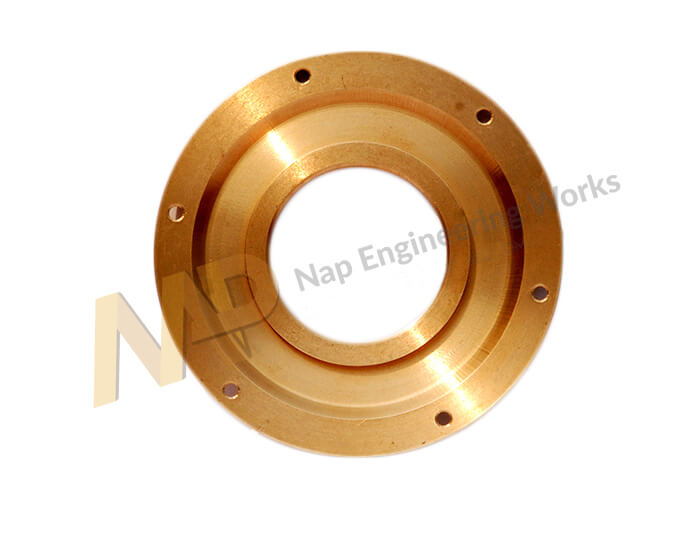

Description

Renowned Leaded Tin Bronze Casting Manufacturer Near You

NAP Engineering Works is a prominent name in leaded tin bronze casting manufacturing and supply. Considering the fact that leaded tin bronze castings are easy to install, it is a popular choice among different industries. Leaded tin bronze casting manufacturers consist of 10 to 12 % of tin and other alloy elements. We keep in mind two major factors for the manufacturing process of this casting they are – durability and efficiency of the casting materials.

You can trust us with leaded tin bronze castings because we focus on manufacturing the same from the most premium grade materials. We aim to ensure the best customer satisfaction rate in the manufacturing and supply leaded tin bronze castings.

Why Do Industries Prefer using Leaded Tin Bronze Castings?

The main function of the leaded tin bronze castings is to improve machinability. At NAP Engineering Works, we get industrial clients who love using leaded tin bronze castings instead of other options. If you ask why then here are the answers:

- They are highly corrosion resistant.

- They are stable in terms of dimensions.

- They are very efficient in terms of industrial performance.

- They are abrasion-resistant and hence have good longevity.

- This type of alloy also possesses a high degree of hardness and can be easily used as a casting material.

- They have excellent anti-frictional quality and are undoubtedly a popular choice for the industries.

High leaded tin bronze castings by NAP Engineering Works are commonly found in common day applications. We supply leaded tin bronze castings used in cable connectors, rolling mill bearings, doorknobs and screws, and electrical plug-in connectors.

Why Select NAP Engineering Works for Leaded Tin Bronze Castings?

- We are the renowned leaded tin bronze casting manufacturers providing the best quality leaded tin bronze castings for all industries.

- We keep special attention on the quality to ensure complete customer satisfaction.

- We focus on customising the bronze castings to ensure the best use of the same in different industries.

- We use premium quality alloying materials for the casting process.

- We have a team of experienced and qualified engineers to cast the products successfully.

Are you thinking of getting the best casting for your industrial products? For the right set of solutions, approach NAP Engineering Works. Our engineers will help you in the process and ensure utmost satisfaction.